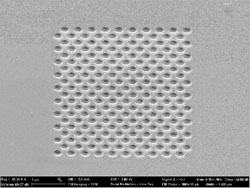

The focussed ion beam (FIB) is a multi nanofabrication tool system capable of performing sophisticated lithography, nanomachining, in-situ metal or insulator deposition and metrology analysis. This versatile system is based on the dual ion and electron beams column concept, which allows it to perform ion-based nanofabrication function while imaging using the scanning electron microscope. The ion beam is derived from a gallium source integrated to an ionisation tungsten tip. This produces very high resolution direct write lithography as an alternative to electron beam lithography.

Zeiss NVision 40 CrossBeam FIB System

The Zeiss NVision 40 FIB system offers the combination of three dimensional direct ion beam lithography and milling. The FIB column is integrated to a field emission scanning electron microscope which gives researchers a unique opportunity to perform direct write, image and close examination of their devices simultaneously at nanometer scale resolution. The NVision 40 is an ideal and versatile tool for nanofabrication and nano-engineering applications in semiconductor to biological materials. It allows fast prototyping of micro-nanodevices and structures before committing to large scale fabrication process. The ion beam has a lithography resolution of 4 nm and the system has a pattern generator that is capable of large writing field of hundreds of micron. Designed patterns such as in GDS file format can be imported into the system and immediately reproduced. The FIB system can also be used for optical mask and in-situ device components repair function. In addition, it has metallic and insulator in-situ deposition feature with electron beam or ion beam assisted function. This is available from the gas injection system (GIS) unit providing deposition material such as tungsten, carbon and silica. It is also equipped with xenon difluoride gas for ion-assisted etching process.